Get Rid of Conveyor Belt Maintenance Issues-- Asphalt Plants.

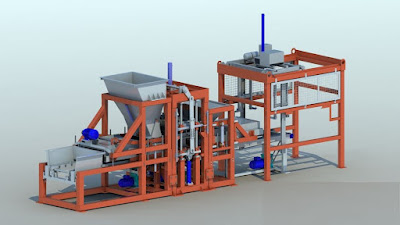

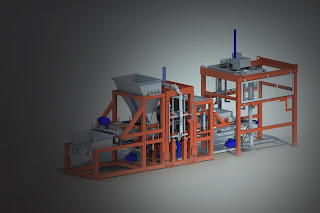

The proper functioning of conveyor belts maintenance are very important to smooth operation of asphalt batching plant or concrete mixers. Conveyor belts should be maintained along with the frame holding the conveyor belt. The operator or maintenance personnel should be well versed with the basic maintenance of conveyor belt and its entire frame. Heat-resistant conveyor belt on Atlas double drum asphalt plant. The maintenance personnel should regularly walk around both the sides of the system. And note the physical condition of the conveyor. Any unusual behavior of moving components must be taken note. Any material getting stuck has to be noted. Signs of misalignment or improper belt tracking have to be noted. Drive amperage requirements has to be checked. The same thing has to be compared to previous levels for similar loads and conditions or adjusted to the manufacturers standard. Few things that the operator can take care of are: Some few things that asphalt plant operator is very...