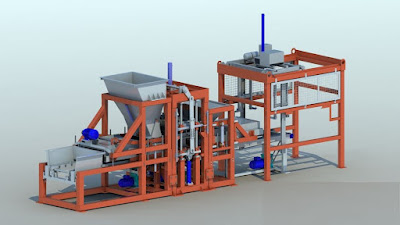

Asphalt Batch Plant First Time Start UP

When the equipment arrives to the job site in a dismantled condition it becomes very important to install each component properly and take a dry trial run of them prior to the actual mix run. Below are some important points to note for the first time start-up of Atlas asphalt batch plant. Atlas does support its customers with on site support for installation, operation and maintenance of the equipment. All the points are usually checked and taken care of by our technicians physically as they are present at the site. Due to COVID-19 we are unable to send our technicians to many job sites and hence this guide comes handy. Things to Note Before Starting the Asphalt Batch Mix Plant - All moving parts have to be greased before starting the plant. - Oil to be filled in all the components before starting the plant. - All feeder belts have to be set and aligned before starting the plant. - After the first empty run, all nuts and bolts of the plant have to be tightened. - The first 5-6 ...