The Appropriate Maintenance For Asphalt Pavement That Wins Customers

Asphalt is among the most prevalent clearing materials utilized today because of its water-resistance, adaptability, stylish interest, and magnificent cement capacities. These properties and more make asphalt pavement an advantage that requires a structured level of conservation and care. With proper deterrent maintenance, asphalt pavements can stay utilitarian and lovely for years. Asphalt Maintenance In spite of the fact that asphalt maintenance motivation will contrast from property to property, the general reason for black-top support is to maintain its appeal and amplify its life. Some maintenance support undertakings can be managed all alone or by an appointed staff, for example, assessments and waste clearance; while others are best left in the hands of prepared and equipped experts. A perfect asphalt support ought to incorporate fundamental assignments like standard assessments, clearing, break filling, pothole repair, intermittent line striping, and in particular, seal coating. Without an appropriate seal coat, asphalt pavements will encounter heightened wear and tear from traffic, climate, chemicals, salts, and more, which abbreviates their life and reduces their aesthetic value.

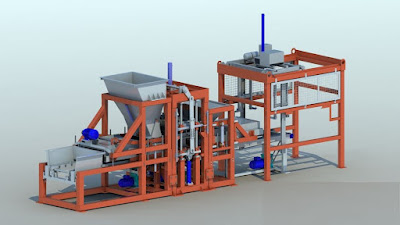

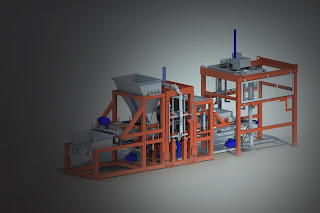

Asphalt Seal Coating Seal coats are emulsions that are brushed or showered onto pavements, providing an unmistakable defensive layer against moisture and the previously mentioned threats. There are a few sorts of commercial seal coats accessible available, however, the most well-known variants include mist seal, slurry seal, and chip seal emulsions. Fixing Coat It won't likely benefit from another layer of seal coat if your black-top asphalt is old and in poor condition. In some cases, it is savvier to repair or supplant decayed asphalt pavements. If your asphalt is in great condition, an occasional re-fixing can be an exceedingly valuable maintenance choice. Asphalt batch mix plant.

|

| Image:- Asphalt plant manufacturer - All Tech Group. |

Converse with your trusted paving contractor for an expert proposal of your asphalt's maintenance and seal coating plan. They will know precisely what your property needs and at what interim. The cost of having your asphalt seal-covered will rely on upon a few components, for example, the square film, the state of pavement, and any extra surface applications required.

We are leading manufacturer, supplier and exporter of road

construction machines and equipment such as asphalt batch mix plant, wet mix

plant, asphalt road paver finisher, asphalt drum mix plant, asphalt storage

tank and more products. Team Solid offers Asphalt Mixing Plant after

considering the feedback of the actual end users on site. The mixing plants are

innovatively designed, user friendly giving hassle free operation. Uttermost

care has been taken to reduce the over all implementation cost and finally the

operating cost to make them suit the extreme working conditions. With proper

deterrent maintenance, asphalt pavements can stay utilitarian and lovely for

years. What is asphalt batch mix plant?

In spite of the fact that asphalt maintenance motivation will

contrast from property to property, the general reason for black-top support is

to maintain its appeal and amplify its life. Without an appropriate seal coat,

asphalt pavements will encounter heightened wear and tear from traffic,

climate, chemicals, salts, and more, which abbreviates their life and reduces

their aesthetic value. If your black-top asphalt is old and in poor condition,

it won't likely benefit from another layer of seal coat. Converse with your

trusted paving contractor for an expert proposal of your asphalt's maintenance

and seal coating plan.

Comments

Post a Comment