Asphalt Drum Mix Plant Operation And Components

Hot mix asphalt is made by an asphalt mixing plant. HMA stands for hot mix asphalt. This hot mix asphalt is widely used in road construction. A specific recipe is used to make hot mix asphalt. It is composed of various types of aggregates, bitumen and filler material. There are many sizes of aggregates.

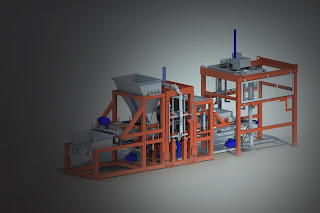

Here are some hot mix plants examples:

These asphalt mixers can be used to make hot mix asphalt. HMA is possible, even though the process is quite unique. HMA is produced in batches rather than by continuous (drum) plants. High quality end products can be produced by batch plants, which are more reliable and advanced. They are also more expensive to buy and maintain. Drum plants are easier to set up and less expensive to maintain.

Mixing drums is the most important task of a drum mix asphalt plant. The plant heats the aggregates evenly and then mixes them with bitumen, or other filler material. Dry drums have an inclined structure and a cylindrical shape. A burner unit is located at the drum's higher end. Here the aggregates heat up. The first half of the aggregates will be heated and then the second will be mixed with bitumen, or other filler material.

The filler material is stored in separate areas, in a container. This material is transferred to the dryer drum by the compressor. The amount of filler material used will be determined by the control panel. Then, the aggregates are matched.

Asphalt drum mix plants are made up of many components. All of them work together to create the best hot mix asphalt. It is important that all components of the drum mix asphalt plant work together.

These are the key components of an asphalt drum mixing plant.

Stationary plants are preferred by customers who require long-term production in one location. Stationary plants are better suited for long-term production in one location. Mobile plants can produce small to medium amounts of material in different places. Mobile plants can be moved from one place to another. Mobile plants are generally easier to setup and manage than stationary plants.

Mixer asphalt drum plants can be very easy to maintain and own. Mixer asphalt drum plants are much smaller than batch machines. This is their greatest advantage. They are lightweight and easy to set up.

Here are some hot mix plants examples:

- Batch type – It produces hot asphalt mixture in small batches.

- Drum/continuous type: This is HMA in continuous process.

These asphalt mixers can be used to make hot mix asphalt. HMA is possible, even though the process is quite unique. HMA is produced in batches rather than by continuous (drum) plants. High quality end products can be produced by batch plants, which are more reliable and advanced. They are also more expensive to buy and maintain. Drum plants are easier to set up and less expensive to maintain.

|

| Image:- Asphalt Batch mix plant Supplier - All Tech Group |

Asphalt drum mix plant operation (working)

- The operation of an asphalt drum mix plant begins with the addition of aggregates to cold aggregate bins. When hot mix asphalt is produced to the desired quality, operation of a drum-mixer is complete.

- These are the fundamental principles of asphalt drum plant operation.

- All cold feeder bins should be filled with aggregates. These aggregates come in different sizes and are placed in their own bins. Bins can be synchronized separately to ensure a controlled flow of aggregates.

- A single-deck vibrating screen is used to pass aggregates. This screen removes larger aggregates and stops them from entering the drum.

- Asphalt plants use a charging conveyor for transporting the aggregates to drying and mixing drums. The charging conveyor is equipped with a load cell to weigh the aggregates prior to entering the drying and mixing drum.

- The load cell receives data from the computer and transmits it to a computerized panel. This panel will control the flow of bitumen and filler material.

- The bitumen is stored in separate tanks with burners. Once the control panel receives the data, the bitumen tank can be used to add bitumen to the drum using bitumen pumps. This bitumen pump is connected to the control panel. Bitumen flow is controlled by the variable speed drive motor.

Mixing drums is the most important task of a drum mix asphalt plant. The plant heats the aggregates evenly and then mixes them with bitumen, or other filler material. Dry drums have an inclined structure and a cylindrical shape. A burner unit is located at the drum's higher end. Here the aggregates heat up. The first half of the aggregates will be heated and then the second will be mixed with bitumen, or other filler material.

The filler material is stored in separate areas, in a container. This material is transferred to the dryer drum by the compressor. The amount of filler material used will be determined by the control panel. Then, the aggregates are matched.

|

| Image:- Asphalt Batch Mix Plant Manufacturer - All Tech Group |

Once the material is properly mixed in the drum unit, it will be transferred to the trucks via a conveyor. Some plants may have a hot storage silo for temporary storage. Another important component is the control panel unit. It connects to all other components to control material proportions.

Asphalt drum mix plants are made up of many components. All of them work together to create the best hot mix asphalt. It is important that all components of the drum mix asphalt plant work together.

These are the key components of an asphalt drum mixing plant.

- Cold aggregate feeder bins

- Slinger / charging conveyor

- Drying and mixing drum

- Bitumen tanks

- Mineral filler unit

- Control panel

Stationary plants are preferred by customers who require long-term production in one location. Stationary plants are better suited for long-term production in one location. Mobile plants can produce small to medium amounts of material in different places. Mobile plants can be moved from one place to another. Mobile plants are generally easier to setup and manage than stationary plants.

Mixer asphalt drum plants can be very easy to maintain and own. Mixer asphalt drum plants are much smaller than batch machines. This is their greatest advantage. They are lightweight and easy to set up.

Article Credit:- All Tech Group.. All Tech Group is manufacturer and exporter of asphalt batch plant, batch mix plant, counter flow drum mix plant,.

Comments

Post a Comment