Asphalt Batch Plant First Time Start UP

When the equipment arrives to the job site in a dismantled condition it becomes very important to install each component properly and take a dry trial run of them prior to the actual mix run. Below are some important points to note for the first time start-up of Atlas asphalt batch plant. Atlas does support its customers with on site support for installation, operation and maintenance of the equipment. All the points are usually checked and taken care of by our technicians physically as they are present at the site. Due to COVID-19 we are unable to send our technicians to many job sites and hence this guide comes handy. Things to Note Before Starting the Asphalt Batch Mix Plant

- All moving parts have to be greased before starting the

plant.

- Oil to be filled in all the components before starting the

plant. - All feeder belts have to be set and aligned before starting the plant.

- After the first empty run, all nuts and bolts of the plant

have to be tightened.

- The first 5-6 batches of plants operation have to dry batch.

After that, tighten the vibrating screen nut bolts and mixer

arms and tips and liner tighten and weld the same. When viewed from the burner

side,

|

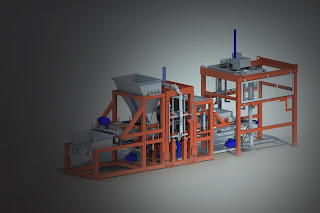

| Image:- Asphalt batch mix plant - All Tech Group |

- Drum should rotate clockwise.

- Opposite to the drum drive gear box there is an idler

sprocket. Its shaft has to be daily greased.

- Dryer drum ring and sprocket has to be oiled and greased

daily. - Check the position of the burner blower motor rotation.

- Vibrating screen motors should be rotating in the opposite

directions.

- One motor should rotate in clockwise and the other motor in

anticlockwise direction.

- The Elevator side motor should rotate clockwise and the

other motor anticlockwise.

- Aggregate weighing hopper and hot bin gate cylinders open

to open the gates.

- Mixer paddle arms rotation from gear side should be in such

a way that the right shaft is rotating clockwise and left shaft is

anticlockwise.

- Check only one motor (shaft) at a time. When viewed from

the motor side should be rotating anti-clockwise,

- Exhauster impeller.

- Check oil level in air compressor before starting the

plant.

- Remove air from the compressor at the end of each day's

operation. - Remove water from the compressor's tank each morning.

- Bag filters has to be heated for 20-30 mins before starting

of operation daily.

- During this time run the bag filter exhausted, drum and

burner blower on at very low temperature (flame).

- Before shutting down the plant run the dryer empty for 30

mins (without any material).

- During this time the burner blower, bag filter cleaning

mechanism, bag filter bottom screw, exhausted should be on.

- When the plant is shut down all the components should be

empty including the hot bins.

- Last batch from the mixer has to be dry batch without

bitumen, without binder so that the mixer is cleaned.

- The plant will not be running to its maximum capacity for the first few days. Only after the initial few days of operation, it is advisable to increase the batch size.

Comments

Post a Comment