Pollution control systems of asphalt plant

Since the dust collection system is integrated with the asphalt plant, the operator is required to be aware with the controls and maintenance standards. The operator is also supposed to be aware of how the dust collector system performance affects the properties of the hot mix asphalt. Major air pollution concern is the dryer burner. A clogged or a dirty burner and or improper air to fuel ratio can result in excessive smoke and also other combustion by products. Close attention and cleanliness in maintaining and adjustments of burners and accessories is important. Dust emissions can be kept under control by use of anti pollution equipments. The common types of dust collectors that are used to capture dust are multi cyclone dry dust collector; venture type wet dust collector and bag house. Maintenance and cleaning of the duct line connecting the dryer and the dry dust collector is as important as maintaining the pollution control systems. This is very important as clogging will not deliver good results. Usually the duct line can be inspected every month but if the dust is more, it has to be done frequently. The exhaust form the dryer drum draws the dust from the duct line towards the multi cyclone dry dust collector.

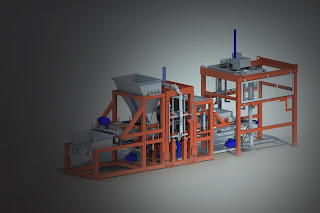

Image:- Asphalt batch mix plant manufacture- All Tech Group

Dry dust collectors are used in combination with either venture type dust collectors or bag house filter. Maintenance and cleaning of dry dust collector has to be done every month or less if the dust is more. The aim of wet dust collector is to trap the dust particles in water droplets and remove them. Most of the wet dust collectors are used in connection with cyclone separators (dry dust collectors). The flow of water is in the opposite direction of the dust suction allowing entrapment of large particles and treating them to cyclonic effect before settling the sludge. What is asphalt plant?

The water is then collected into a sludge pond which has to be periodically cleaned. The wet dust collector has to be periodically cleaned and inspected so that water flows freely. Water spray nozzles have to be regularly cleaned for clogging and to ensure smooth operation. Bag house filters is the best way to contain aggregate dust. Bag house filter works on the principle of vacuum cleaner as it creates vacuum and sucks the dust filled air towards the bags. A bag house is a huge compartment having numerous heat resistant fabric bags for collection of fines. Asphalt batch mix plant.

Since the volume of the gases to be handled is huge, a very

large number of bags are required. The filter bag accumulates the particles as

the gas passes through the bags. This will, over a period of time, result in

accumulation of dust which will require periodic cleaning or it can stop the

flow of gas form the chamber. Dust collected can be wasted or reused. The

common types of dust collectors that are used to capture dust are multi cyclone

dry dust collector; venture type wet dust collector and bag house. The exhaust

form the dryer drum draws the dust from the duct line towards the multi cyclone

dry dust collector. Dry dust collectors are used in combination with either

venture type dust collectors or bag house filter. Maintenance and cleaning of

dry dust collector has to be done every month or less if the dust is more. Most

of the wet dust collectors are used in connection with cyclone separators (dry

dust collectors).

Comments

Post a Comment