The Way An Asphalt Batch Mix Plant Functions

Mixing different sizes and grades of aggregates in asphalt mix plants produces asphalt material. These aggregates are mixed with the appropriate amount of liquid bitumen, and heated together to create hot asphalt mixture. Asphalt is a mix of bitumen and pulverized stones that is used for making pavements.

There are a few factors that determine the characteristics and quality of an asphalt mix. These factors include the amount of aggregate used and the type or recycled pavement.

How does hot mix asphalt get made? Once the aggregates have dried, they are heated to coat them with bitumen. You can dry the aggregate by rolling it in a dryer drum. To evaporate dampness and generate heat, the dryer drum is heated to below. The aggregate remains in the top half of drum. The interior contains several types of flight that heat the drum. The mixing chamber is where the aggregates are covered with bitumen.

There are two main types of asphalt plants.

Mixing begins when aggregates are removed from feeders. The aggregates are then moved by a conveyor to a drying drum. This drum has an internal flight that quickly dries the contents. The aggregates are then transported outside to the drying drum, where they are separated through sedimentation. The aggregates are then sorted according to their size and placed in the hot bins.

Once the aggregate sizes are sorted and controlled they can be allowed to enter the mixing chamber. The aggregate sizes are then combined with bitumen in a controlled quantity. The bitumen is taken directly from the container. It is then stored at high temperatures. The product is delivered in the right proportions by the mixing unit. The mixture is ready to be discharged. It is then unloaded from the hot storage silo. It can be loaded on a truck if it is ready to transport.

Parallel Flow Drum Plants – Functioning

Parallel flow drum asphalt plants produce asphalt continuously unlike batch-producing plants. Parallel flow drum asphalt plants only require one dryer to dry and mix. The dryer is used for drying the mixture and mixing it with bitumen. The mixture is weighed as it moves from the cold feed bins to the mixing drum via the charging conveyor belt. After the mixture has been weighed it is placed in the drum's lower section to be stored in one the silos. You can also load the mix directly into a truck to transfer it immediately. Asphalt mixers that utilize parallel flow can be used with both dry and wet types of pollution control systems. There are a variety of capacities available, ranging from 40 tph to 200 tph.

There are a few factors that determine the characteristics and quality of an asphalt mix. These factors include the amount of aggregate used and the type or recycled pavement.

How does hot mix asphalt get made? Once the aggregates have dried, they are heated to coat them with bitumen. You can dry the aggregate by rolling it in a dryer drum. To evaporate dampness and generate heat, the dryer drum is heated to below. The aggregate remains in the top half of drum. The interior contains several types of flight that heat the drum. The mixing chamber is where the aggregates are covered with bitumen.

|

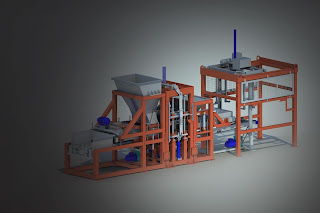

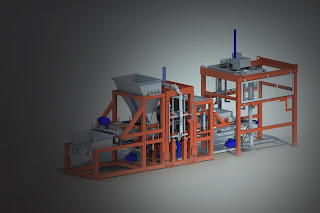

| Image:- Asphalt Batch Mix Plant Manufacturer - All Tech Group |

- Asphalt is produced in small batches by the batch plant, also known to be called the discontinuous tower plant.

- Drum plant also known as continuous plant. This plant is capable of producing asphalt continuously, without any stopping. These plants can work in parallel or against flow

Mixing begins when aggregates are removed from feeders. The aggregates are then moved by a conveyor to a drying drum. This drum has an internal flight that quickly dries the contents. The aggregates are then transported outside to the drying drum, where they are separated through sedimentation. The aggregates are then sorted according to their size and placed in the hot bins.

Once the aggregate sizes are sorted and controlled they can be allowed to enter the mixing chamber. The aggregate sizes are then combined with bitumen in a controlled quantity. The bitumen is taken directly from the container. It is then stored at high temperatures. The product is delivered in the right proportions by the mixing unit. The mixture is ready to be discharged. It is then unloaded from the hot storage silo. It can be loaded on a truck if it is ready to transport.

Parallel Flow Drum Plants – Functioning

Parallel flow drum asphalt plants produce asphalt continuously unlike batch-producing plants. Parallel flow drum asphalt plants only require one dryer to dry and mix. The dryer is used for drying the mixture and mixing it with bitumen. The mixture is weighed as it moves from the cold feed bins to the mixing drum via the charging conveyor belt. After the mixture has been weighed it is placed in the drum's lower section to be stored in one the silos. You can also load the mix directly into a truck to transfer it immediately. Asphalt mixers that utilize parallel flow can be used with both dry and wet types of pollution control systems. There are a variety of capacities available, ranging from 40 tph to 200 tph.

Article Credit:- All Tech Group. All Tech Group is manufacturer and supplier of asphalt batch mix plant, asphalt plant, counter flow drum mix plant,

Comments

Post a Comment